Introduction

The way we package fresh meat, fruits, and vegetables is undergoing a quiet revolution. Driven by environmental regulations, supply chain demands, and shifting consumer expectations, the future of produce packaging is leaning hard toward sustainability, functionality, and transparency. Foam trays, plastic clamshells, and multilayer films—once considered essential—are now under scrutiny for their environmental toll.

But packaging still has a crucial job to do: it must protect, preserve, and present. The challenge now is how to meet those needs without relying on single-use plastics.

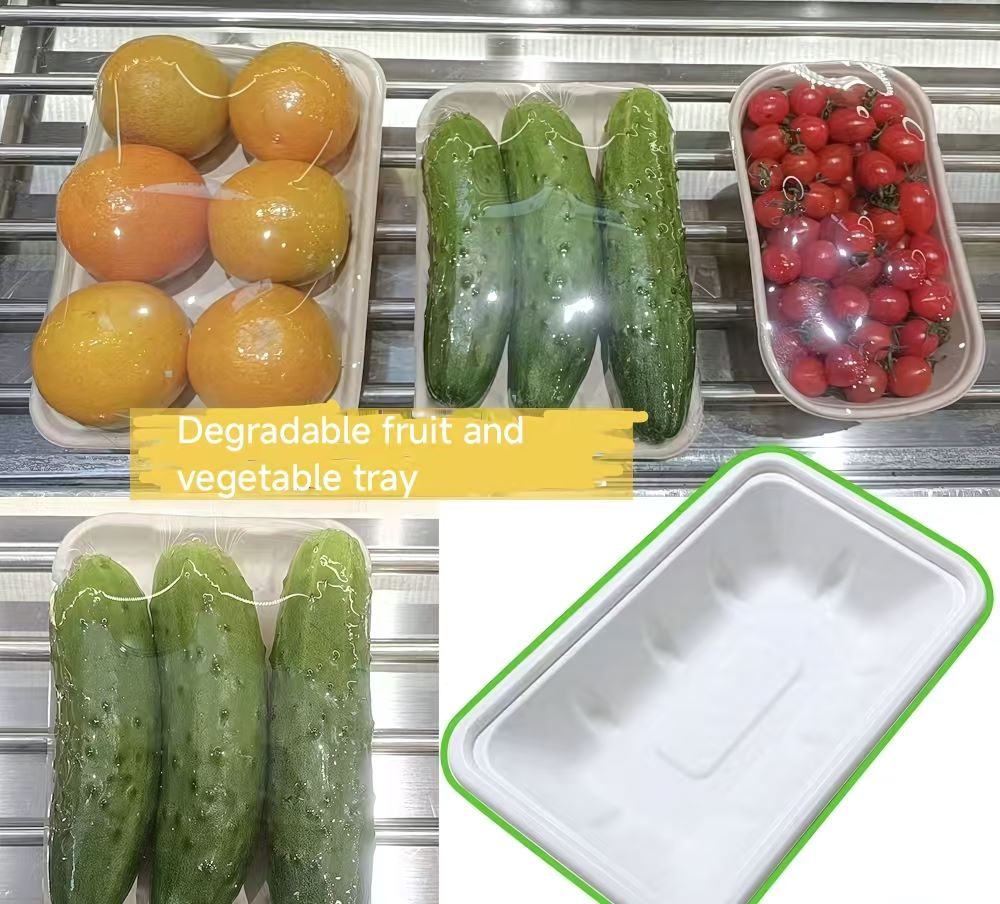

Among the leading alternatives gaining traction are molded fiber trays made from sugarcane pulp. They blend sustainability with practical performance, offering a plant-based solution that works across cold-chain logistics, retail display, and food safety requirements.

In this article, we explore the key forces reshaping meat and produce packaging—and why compostable molded trays are emerging as a frontrunner in the future of fresh food distribution.

Why Produce Packaging Must Evolve

Traditionally, meat and produce have been packaged in plastic or foam trays to maintain freshness, prevent leaks, and support safe transport. However, there’s growing pressure to replace these with sustainable solutions:

- The global meat packaging market was valued at US $16 billion in 2024, with food-safe packaging and sustainability driving its 4–5% annual growth

- Food waste remains a critical issue: around 50 % of fresh produce is lost between harvest, transport, and sale—often due to inadequate packaging or cold-chain breaks.

- Regulations like North America’s plastic bans and EU directives are accelerating demand for alternatives.

Farms, grocers, and exporters now seek packaging that is safe, protective, aesthetically pleasing, AND eco-friendly. Compostable trays made from molded pulp tick all these boxes.

What Makes a Great Produce Tray?

Fresh produce packaging faces multiple demands across the supply chain. From harvesting sites to retail shelves, trays must balance functionality with sustainability. A well-designed tray for meat, fruits, or vegetables should meet the following criteria:

- Food-Safe: It must comply with food contact regulations, ensuring no chemical migration or contamination risks.

- Cold-Chain Compatible: Since most fresh produce—especially meats—requires refrigeration or freezing, the packaging must remain stable in low-temperature environments.

- Breathable: Proper ventilation helps minimize moisture buildup, reducing the risk of mold or spoilage during transport and storage.

- Brandable (without excess packaging): While many packaging formats rely on stickers or sleeves, good trays can support branding directly through texture or form.

- Efficient to Store & Stack: Space-saving stackability is critical for logistics, whether in cold storage or high-turnover retail display.

Our molded fiber trays, made from sugarcane bagasse, are designed with these exact criteria in mind. They are certified food-safe (FDA, EU, and REACH), structurally sound even when frozen, and feature a naturally porous surface that helps manage internal moisture levels.

In addition, trays can be customized with embossed logos during molding—offering subtle brand recognition without the need for labels. Their flat-top geometry ensures clean stacking for efficient shelf display and distribution.

In essence, a great produce tray doesn’t just hold your product—it supports your supply chain, your brand, and your sustainability goals all at once.

Why Molded Pulp Trays Are Gaining Ground

The global compostable packaging market is booming, valued at around US $74 billion in 2023 and poised to grow at a 6–8% CAGR in the coming decade. Molded fiber trays are particularly attractive for several reasons:

- Sustainable Origin: Made from agricultural byproducts like sugarcane bagasse, it’s renewable and often sourced locally.

- Eco Brand Boost: Plastic-free trays resonate with environmentally-minded consumers and businesses.

- Regulatory Alignment: Increasing bans on single-use plastics mean rapid adoption by progressive food retailers.

- Performance Parity: These trays match plastic in strength yet offer compostability at end-of-life.

InNature Pack specializes in molded fiber tray solutions that meet real-world needs while supporting brand and regulatory goals.

Applications Across the Supply Chain

Farms & Harvest Facilities

Pre-made trays for packing produce (like carrots or berries) at the source reduce repackaging downstream, cutting handling time and plastic waste.

Retail & Supermarkets

Whether displaying fresh meat cuts or salad kits, these trays support clear, low-condensation presentation. Pair with PLA film to match consumer demand for transparency and eco-friendliness.

Export & Cold Chain

Our sugarcane pulp trays are chlorine- and toxin-free, meaning they can withstand transit without breaking or contaminating the contents, ideal for cross-border export.

Meal Kit & Delivery Services

Clean, stackable design paired with natural textures complements eco-conscious meal brands and supports consumer lifestyle trends without plastic footprint.

- Material Innovation: Combining bagasse pulp with wheat straw or bamboo fiber for lower cost and improved stiffness.

- Traceability Tools: Digital solutions (e.g., QR-coded trays) are being adopted alongside IoT systems to improve supply-chain transparency.

- Regulatory Momentum: Policies like Europe’s plastics directive and North America’s recyclability targets are pushing compostable trays to the forefront.

- Consumer Brand Preference: Eco-branded meat trays are increasingly used as marketing assets—reinforcing brand integrity.

Subtle Product Integration

At InNature Pack, we provide molded sugarcane fiber trays designed for meat, produce, and berry applications. With structural strength, breathability, and food safety certification, our trays are ready for daily use in both chilled and frozen environments—from homestead farms to national retail chains.

Through embossed mold details and options like PLA film top sheets, you can minimize your plastic output—cutting it by more than half. The trays remain practical while delivering that “rooted-in-nature” brand experience customers appreciate.

Conclusion

Compostable molded pulp trays are not just a future possibility—they’re a present solution. From farmpacking to shelf detailing, these trays deliver the rigor, safety, and visual consistency expected in meat and produce packaging—without the heavy plastic footprint.

If your operation is exploring sustainable packaging, consider experimenting with compostable trays and eco-friendly films. InNature Pack is ready to help you identify options tailored to your supply chain and product characteristics. Let’s make packaging a market differentiator—naturally.

FAQ

Q1: Do sugarcane trays work for freezer meat packaging?

Yes. They remain structurally sound at typical freezing temperatures and pair well with food-safe PLA or PE films.

Q2: How does air flow help produce freshness?

Micro-pores in molded fiber reduce condensation—proven to reduce spoilage in cooling trials .

Q3: Can my brand logo be added?

Yes. Our trays support logo embossing via the mold, so the branding is permanent and discreet.

Q4: Is composting easy at home?

Most bagasse trays will break down within 90 days in a home compost bin. Industrial compost systems degrade them even faster.

Q5: What are the minimum order quantities?

MOQ varies by design. Please reach out with your SKU needs, and we’ll provide tailored details.