Both cornstarch packaging and bagasse tableware provide food businesses with innovative ways to reduce waste. They are increasingly used by cafés, catering services, and takeaway joints wanting to fulfil eco credentials.

Cornstarch is produced from plant-based starch (typically corn), while bagasse is made from the fibrous pulp left after sugarcane is processed. Both materials decompose much faster than traditional plastic in landfills or commercial composting systems.

As single-use food packaging continues to evolve, these two options stand out for their environmental benefits and growing popularity. While they serve similar functions in food service and takeaway, each comes with its own set of strengths.

The following sections compare how each performs in key areas—such as price, strength, heat resistance, and sustainability—helping businesses make informed choices based on their specific needs.

Material Origins and Composition

Food businesses are under increasing pressure to choose packaging that does right by the planet. Two of the best alternatives, cornstarch and bagasse, have emerged as eco-friendly options for plates, bowls and takeaway containers. They are both derived from farm crops – corn and sugar cane – and they represent an escape from plastics.

Selecting the sustainable option isn’t just about ticking a box. It powers waste, supports local growers and changes the way food moves from kitchens to customers.

Cornstarch: From Farm to Plate

Cornstarch packaging starts with corn, which is primarily grown on farms. The corn kernels are processed through fermentation and polymerization to extract and convert starch into a bioplastic called polylactic acid (PLA).

This means cornstarch can be transformed into forks, spoons, and boxes — but it’s not suitable for all types of food. PLA tends to warp under heat, making it less ideal for hot items like chips or pies.

Most cornstarch packaging requires a thin lining to prevent leaks and grease penetration. However, these linings can interfere with composting because some coatings do not decompose as quickly

Bagasse: Sweet Sugarcane’s Second Life

Bagasse is what’s left from squeezed sugarcane stalks. Rather than discarding this mash, it’s compressed and formed into plates and trays. Using bagasse is less farm waste and less need for new crops.

Bagasse is durable, heat-resistant, and composts quicker − in around 60-90 days. It slots into a circular economy by taking what’s left behind and cutting landfill.

Making the Goods: A Quick Look

When you’re choosing between cornstarch and bagasse for food packaging, it’s useful to understand how these goods are produced. Both approaches affect how the products behave. It calculates their energy and water needs and how well they break down. Which is why it’s interesting to see what goes into making each and every one. Learn what this means for food businesses trying to cut down on waste!

|

Step |

Cornstarch Packaging |

Bagasse Tableware |

|---|---|---|

|

Raw material |

Corn kernels |

Sugarcane byproduct pulp |

|

Extraction |

Starch separated from kernels |

Pulp leftover after juicing |

|

Forming method |

Vacuum forming or injection moulding |

Moulded from wet pulp |

|

Compost conditions |

Needs industrial composting |

Breaks down at home or industry |

|

Usual breakdown time |

90-180 days (varies) |

60-90 days (reliable) |

Cornstarch Packaging Creation

Cornstarch packaging, for example, begins with extracting starch from corn. The kernels are soaked, milled and then processed to separate the starch. Makers mould the starch into their packaging using vacuum forming or injection moulding.

To decompose swiftly, cornstarch bags require heat, moisture and airflow – conditions that exist only in large-scale composting facilities. If proper, the containers can decompose in 90 to 180 days, but bad composting drags things along. Heat resistance is modest, restricting use for hot foods.

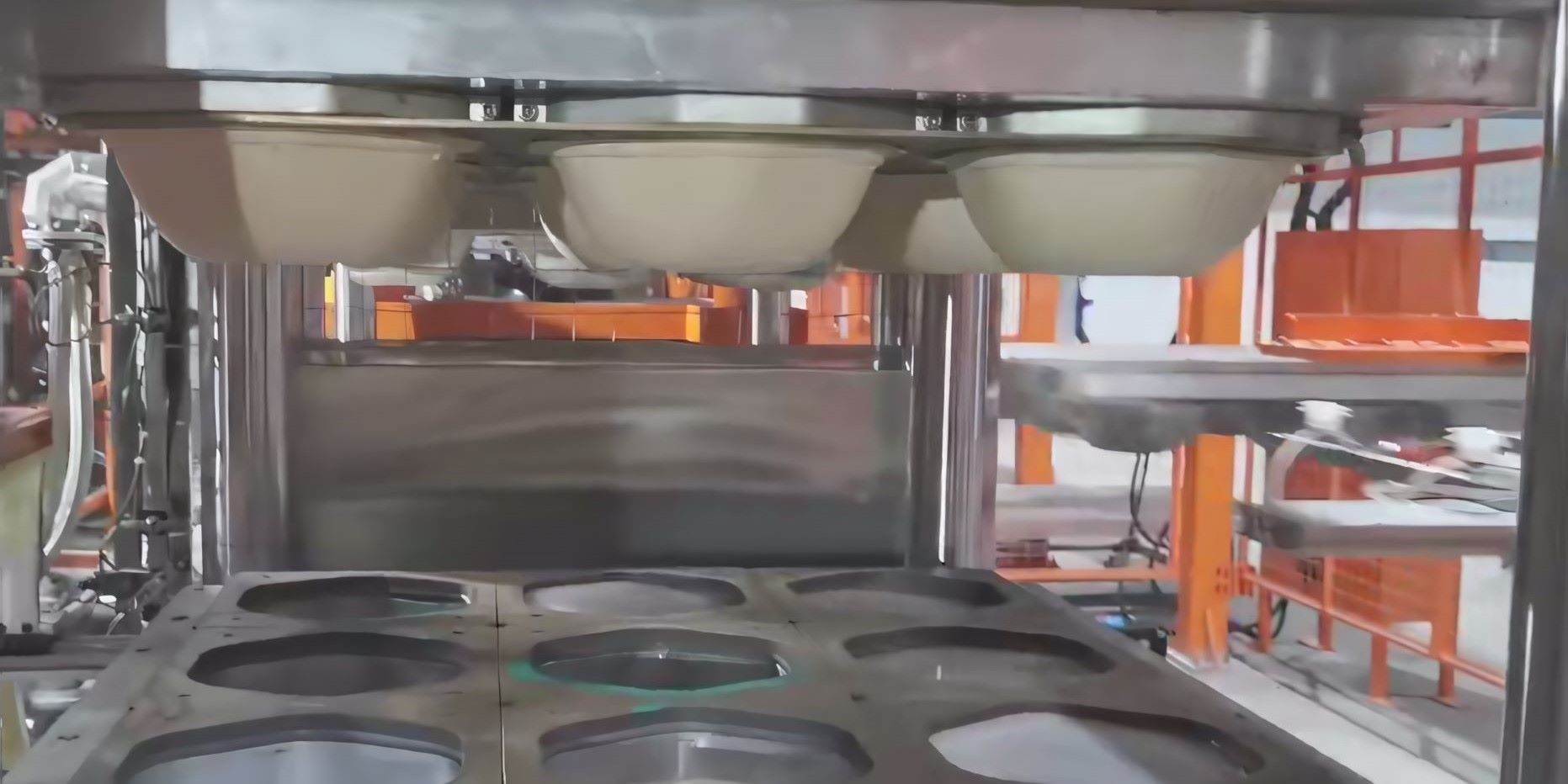

Bagasse Tableware Production

Bagasse tableware comes from sugarcane pulp remaining after the juice has been extracted. The pulp is washed, combined with water, and pressed into shape. This takes less energy than making plastics or cornstarch products.

Bagasse decomposes within 90 days, even in home composts. Utilising sugarcane waste reduces landfill and makes use of byproducts.

Energy & Water: The Hidden Costs

Bagasse requires less water and energy than cornstarch. Cornstarch’s method is lengthier and requires more soaking and rinsing water. More resource use = more planetary impact.

Food companies interested in reducing waste and expense naturally gravitate to bagasse.

Eco-Warrior Showdown: Cornstarch vs. Bagasse

Food businesses are considering green packaging as a genuine means of reducing waste. Cornstarch and bagasse lead the pack. They both have advantages and disadvantages with respect to land use, resources required, compostability, carbon footprint and end-of-life.

1. Land Use & Resource Intensity

Corn needs farmland, typically competing with food supply and dependent on fertilisers and water. Bagasse comes from sugarcane stalks discarded after juice extraction, utilising waste from an already harvested crop.

Using bagasse means less new land is cleared. Sustainable farming techniques, such as crop rotation and judicious water use, reduce land and resource waste for both.

2. Carbon Footprint: From Farm to Bin

Bagasse trumps for lower emissions, requiring less processing energy. Cornstarch’s journey from crop to container has a larger footprint, in part due to energy-intensive factories.

A full lifecycle check reveals bagasse sometimes beats bagasse in low-impact claims.

3. Waterway Impact: The Run-Off Story

Corn farming causes fertiliser and pesticide run-off, which damages rivers and reefs. Sugarcane has its own dangers, but using waste avoids more new planting and often less use of chemicals.

Sourcing from best-practice farms protects waterways and wildlife.

Performance Comparison

When it comes to food packaging, performance in real-world conditions matters just as much as sustainability. Whether you’re serving up hot meals, oily dishes, or moisture-heavy recipes, your packaging needs to hold up under pressure—literally. Below, we break down how cornstarch packaging and bagasse tableware stack up in terms of heat resistance, structural durability, and resistance to moisture and oils.

1. Heat Resistance

Cornstarch packaging typically tolerates temperatures from around -10°C to 100°C, making it suitable for refrigeration, freezing, and short-duration microwave reheating . While it is generally considered microwave-safe, extended exposure to high heat or very hot, oily foods may still cause softening or deformation.

Bagasse tableware, by comparison, is naturally heat-resistant up to around 200°C or more, without the need for additional treatments. It remains stable with hot meals and performs reliably in microwaves, making it better suited for a wider range of hot food applications.

2. Durability & Structural Integrity

Cornstarch packaging tends to warp or weaken under the weight of heavier meals, especially oily or saucy dishes.

Bagasse is a heavier-duty option that maintains its shape and structure, even when used with moist or dense foods. This makes it more reliable for takeout and delivery.

3. Moisture and Oil Resistance

Cornstarch packaging may require a coating layer—often PLA—to resist liquids and grease, which can add to cost and limit compostability in some settings.

Bagasse offers natural resistance to both moisture and oils without the need for additional coatings, keeping things simple and sustainable.

Considerations for Food Businesses

Choosing between cornstarch and bagasse packaging isn’t just about going green—it’s about how each option fits into the realities of running a food business. Beyond compostability, factors like cost, logistics, regulations, visual appeal, and even in-store performance can influence your decision. This section walks through key practical considerations to help you decide which material serves your customers—and your bottom line—better.

Cost: What’s the Damage, Mate?

When comparing pricing, bagasse tableware often comes out as the more affordable option. One key reason is its origin—bagasse is a by-product from sugar mills, meaning it’s readily available and requires less refinement. In contrast, cornstarch packaging involves a more labor-intensive process: corn kernels must be soaked, ground, and processed to extract the starch, often followed by blending with PLA to form usable packaging materials. This adds both time and cost.

While neither material is as inexpensive as conventional plastic, eco-conscious businesses should consider more than just upfront cost. Bagasse products are not only typically cheaper per unit, especially in bulk, but also compost faster—often within 60 days, compared to 90–180 days for cornstarch packaging. That may translate into reduced disposal fees or improved compliance with municipal composting programs, offering long-term savings.

Supply Chain: Getting Your Hands On It

In terms of sourcing and long-term availability, bagasse offers a more consistent and scalable supply chain. Since sugarcane is processed in large volumes globally, the leftover pulp is plentiful and regularly produced, ensuring steady raw material flow throughout the year. This makes bagasse products easier to secure in large quantities and often less prone to supply shocks.

Cornstarch packaging, on the other hand, depends on food-grade corn crops, which are influenced by seasonal harvests, global commodity pricing, and regional competition for edible corn. In times of crop shortages or increased demand for food use, prices can spike and availability may tighten. This makes the cornstarch supply chain more volatile, especially for businesses relying on high-volume, uninterrupted packaging procurement.

Regulations: Keeping it Above Board

Cornstarch packaging, especially when blended with PLA, may face regulatory challenges in certain regions. For example, some EU countries do not classify PLA-based products as plastic-free, which may limit their use in jurisdictions with strict single-use plastic bans.

Bagasse packaging, by contrast, is widely accepted under plastic-free and compostable product regulations. Its natural composition and lower level of industrial processing make it easier to certify for eco-friendly programs and compliance with global sustainability standards.

Customer Appeal: What Do Customers Think?

Sustainability is no longer a niche concern—customers actively prefer packaging that looks and feels eco-friendly. Bagasse tableware has a natural, earthy texture and appearance that immediately signals environmental responsibility. Its matte finish and fibrous surface reinforce the perception of low-impact dining.

Cornstarch packaging, especially when blended with PLA, often offers a clear or semi-clear finish. This transparency is a major advantage for food presentation, especially in salads, fruit cups, or deli items where seeing the contents is part of the appeal. For grab-and-go meals, cornstarch-based containers can appear cleaner and more modern—depending on your target audience.

Ultimately, both materials carry strong sustainable branding, but the look and feel may impact consumer perception and brand alignment more than you think.

Operational Hiccups: The Nitty-Gritty

New packaging can sometimes throw a spanner in the works. While both cornstarch and bagasse are compostable, they behave differently in real-world food service. Bagasse performs better with hot chips, greasy curries, or microwave reheating, making it more versatile for a variety of meals. Cornstarch, on the other hand, may require extra care when serving hot or oily dishes.

To avoid service issues, kitchen staff need proper training to understand which packaging works best for which meals. Misuse can lead to leaks, customer complaints, or wasted product. Beyond the kitchen, clear communication with customers is just as crucial—let them know whether the packaging belongs in the bin, the compost, or should be returned for recycling.

Our Two Cents: Choosing Wisely

Selecting cornstarch versus bagasse for your food business takes a big picture perspective. It requires attention to the minutiae. Both have their pros and cons.

Understand what works for your menu, your customers and your green targets can help you make the right decision.

When Cornstarch Shines for Your Biz

Cornstarch packaging works when you want clear or lightweight containers. Consider, instead, takeaway salads and cold snacks or foods with low moisture.

They stay rigid and smart-looking, which some customers appreciate. If your audience wants plastic-like packaging but to miss the plastic guilt, cornstarch delivers.

Just remember that these items are slow to decompose. If you have a good composting system, it can take between six and 12 months. The energy to produce them tends to be higher than bagasse.

Why Bagasse Might Be Your Go-To

Bagasse, from sugarcane waste, is great for hot/wet foods like curries, pasta or event catering platters. It retains heat nicely, is leak-resistant and decomposes rapidly – usually within three months in industrial compost.

It’s typically cheaper and has a lower carbon footprint than cornstarch. Many diners tend to view bagasse as the greener option, particularly with industrial composting to hand.

Beyond the Hype: A Balanced View

Each comes with its own pros and cons. Your services and your local waste policy will inform your choices.

Your customers’ expectations will help drive you in that direction too. Watch out for certifications like EN13432 to ensure you are really getting compostable products.

Stay tuned for fresh material as this area keeps on rewriting itself.

Quick tips for picking right:

- Match the material to your menu and serving style.

- Check local composting options.

- Look for certified compostable logos.

- Balance cost, eco impact, and customer leanings.

Here’s a side-by-side comparison to help you sort out which material aligns best with your aims.

|

Feature |

Cornstarch Packaging |

Bagasse Tableware |

|---|---|---|

|

Resource Source |

Corn (food crop) |

Sugarcane waste (by-product) |

|

Processing Energy |

High |

Low |

|

Compostability |

Industrial only (6-12 months) |

Home & industrial (under 3 months) |

|

Heat Resistance |

Low to moderate |

High |

|

Cost & Strength |

Higher cost, less robust |

Cost-effective, robust |

|

Presentation |

Lightweight, clear options |

Opaque, sturdy |

Conclusion

Both cornstarch packaging and bagasse tableware offer eco-conscious alternatives to plastic, helping food businesses cut down on waste while projecting a greener image. Cornstarch packaging may appeal for its clear presentation and plant-based origin, but it can fall short in high-heat or oily applications. Bagasse tableware, on the other hand, stands out for its durability, natural resistance to grease and moisture, and suitability for hot foods and microwave use.

Ultimately, your choice should come down to what your operations need most—whether that’s transparency, strength, heat resistance, or compostability.

Curious to see how bagasse performs in real service scenarios?

Try InNature Pack’s range of bagasse-based containers, bowls, plates, and clamshells—trusted by food businesses worldwide for being both tough and sustainable.

Contact us to request a free sample and experience the difference firsthand.

Frequently Asked Questions

What’s the main difference between cornstarch packaging and bagasse tableware?

Cornstarch packaging originates from corn, whereas bagasse tableware is derived from sugarcane pulp. They’re both plant based and compostable but bagasse is more heat and moisture resistant for Aussie food businesses.

Which is better for hot or oily foods?

Bagasse tableware is more resistant to heat and oil than cornstarch packaging. It’s a favourite for hot pies, chips and the curries that dot Aussie menus.

Are these packaging options suitable for takeaway and delivery?

Yes, you can use both for takeaway. Bagasse is more durable for hot or heavy items, whereas corn starch is ideal for salads and cold snacks. Think about your menu and delivery times.

How do costs compare in the global market?

Globally, bagasse tableware tends to be slightly cheaper and more readily available, while cornstarch food containers are more expensive due to import and production costs.

Can I recycle cornstarch or bagasse packaging ?

No, neither would go in normal recycling bins. Composting is preferable.

What’s the environmental impact of each option?

Both decrease landfill waste and consume renewable resources. Bagasse has a lower carbon footprint than cornstarch.