When developing custom molded pulp packaging, many buyers start with an idea of the product’s shape or the amount of protection needed. But one of the most critical—and often confusing—decisions comes before any mold is made: which raw material and production process should you choose?

Both choices directly affect the cost, surface quality, strength, and environmental footprint of your packaging. Yet most clients don’t need to become pulp experts to make the right call—they simply need a clear understanding of how these factors relate to real-world applications.

This guide breaks down what matters most when selecting molded-pulp materials and processes, using insights from InNature Pack’s years of manufacturing experience. You’ll also find references to several in-depth resources on our site, including Dry Press vs Wet Press: A Comprehensive Comparison of Pulp Molding Packaging Processes and A Comprehensive Guide to Molded Pulp Packaging, which explore the technical background in more detail.

Why Material and Process Choice Matters

For molded-pulp products, the phrase “made of bagasse” or “made of bamboo pulp” only tells part of the story. Each pulp behaves differently during forming, pressing, and drying. The dominant fiber (usually the one exceeding 70 % of the formulation) determines the key properties—while smaller amounts of other fibers are blended in to fine-tune color, strength, or drainage behavior.

At the same time, the manufacturing route—whether dry-press or wet-press—decides not only how smooth the surface will be but also how much the mold will cost, how much energy the process consumes, and how fast production can run.

For any buyer planning a new custom design, understanding this interaction between fiber type and production process is the first step toward achieving the right balance of performance, aesthetics, and cost.

Process Overview: How Production Method Affects Cost

If you’ve read our earlier post Dry Press vs Wet Press: A Comprehensive Comparison, you already know that both methods produce excellent molded-pulp packaging—but they serve different purposes.

1. Dry-Press Process

Dry-press follows the sequence forming → air-dry → hot-press → trimming.

By the time the product enters hot pressing, most moisture has already evaporated. The hot-press step therefore lasts only a few seconds, which makes it highly energy-efficient and labor-efficient.

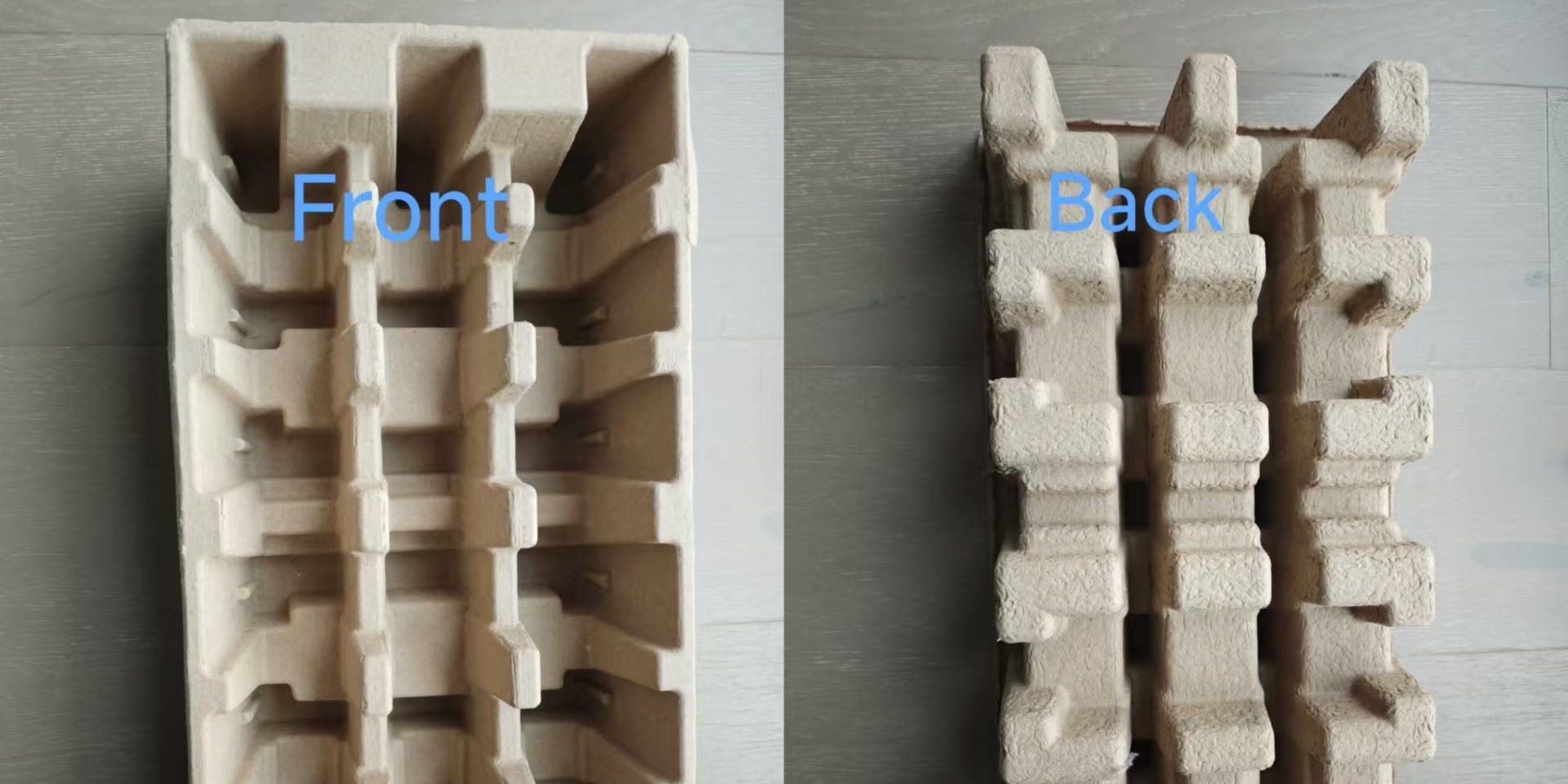

Because the product is semi-dry, the hot press mold can use 1-out-1 structure. In some cases, even no separate trimming mold is required, lowering total mold investment. However, dry-press parts are generally thicker (2 – 3 mm), with a flat front surface and a rougher back.

They are ideal for:

- Large, heavy products that need cushioning

- Industrial or appliance packaging

- Situations where appearance is less critical than strength

2. Wet-Press Process

Wet-press uses the sequence forming → hot-press → trimming.

The product goes into the hot press completely wet, which means each cycle can last around two minutes. That raises energy use and labor time, but it yields a remarkably smooth and detailed surface—perfect for premium applications.

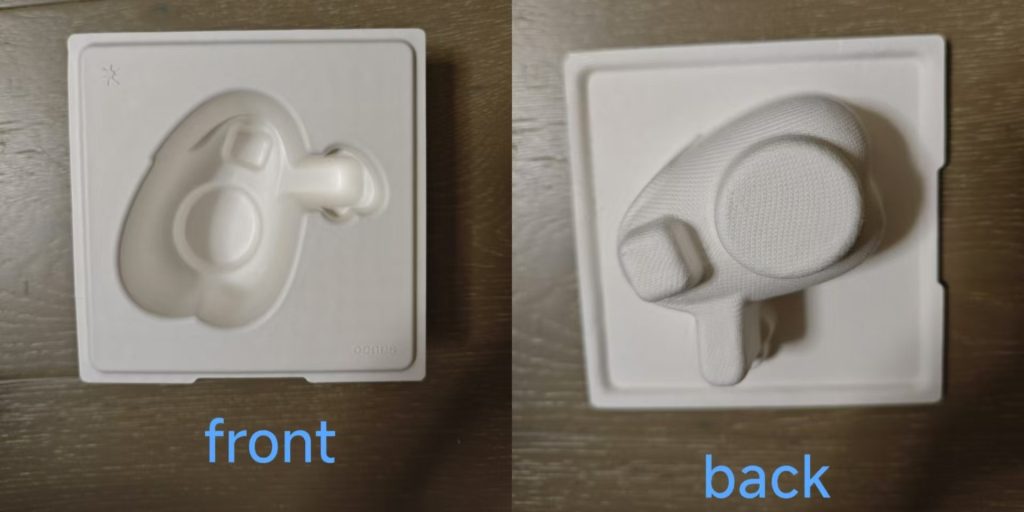

To keep up with forming output, hot-press molds usually include multiple cavities, which makes them more expensive to build. The resulting product, typically around 1 mm thick, is thin, precise, stackable, and visually refined.

Wet-press is widely chosen for:

- Beauty and cosmetic packaging

- Consumer electronics trays

- Food-service disposables (bowls, cups, clamshells, etc.)

- High-end gift boxes requiring elegant appearance

In summary: for packaging products of the same size and fiber type, dry-press molds and unit prices are both lower than those of wet-press, because the dry-press route requires less energy, shorter hot-pressing time, and simpler tooling.

Fiber Material Overview: How Raw Materials Influence Cost and Performance

Every molded-pulp product starts from water and fibers—but not all fibers behave the same way.

At InNature Pack, we work with a full range of renewable virgin fibers and recycled paper pulp, each serving different packaging needs.

When we describe a product as “made of bagasse” or “made of bamboo pulp,” it usually means that this type of fiber is the dominant ingredient—but in practice, every formulation includes a carefully balanced blend of short and long fibers.

This combination helps optimize strength, color tone, and forming performance.

For instance, a packaging piece mainly made from bagasse may include a certain percentage of bamboo pulp to enhance stiffness and achieve a slightly warmer natural hue.

1. Recycled Paper Pulp

- Color: Brown or greyish-brown

- Process compatibility: Mostly dry-press

- Cost level: Lowest

- Applications: Heavy-duty protective packaging for electronics, home appliances, furniture, and logistics trays

- Notes: High strength and cushioning capacity; not food-grade due to potential ink or additive residues.

2. A4 Virgin Pulp (White Pulp)

- Color: Bright white

- Process compatibility: Dry- or wet-press

- Cost level: Moderate

- Applications: General-purpose molded trays or inserts, suitable for both food and non-food uses

- Notes: Made from high-purity wood fiber; provides stable color and smooth forming surface.

3. Bagasse (Sugarcane Pulp)

- Color: Natural warm white

- Process compatibility: Dry- or wet-press

- Cost level: Slightly higher

- Applications: Food containers, cups, bowls, clamshells, and sustainable retail packaging

- Notes: Soft and resilient; 100 % compostable and food-safe. Often mixed with a small ratio of bamboo pulp to enhance strength and color stability.

4. Bamboo Pulp

- Color: Light natural beige

- Process compatibility: Dry- or wet-press

- Cost level: Highest

- Applications: Premium cosmetic, electronics, and gift packaging

- Notes: Dense fiber structure and elegant natural look; favored by brands pursuing a refined, eco-aesthetic identity.

Dyed or tinted pulps are rarely used, unless the client requests a specific Pantone color. In those cases, we only use food-grade dyes.

In summary: for packaging products of the same size and manufactured under the same process, the general cost ranking of raw materials from low to high is:

Recycled pulp < A4 virgin pulp < Bagasse pulp < Bamboo pulp.

How Material and Process Work Together

A good molded-pulp design matches the fiber and the production method to the product’s functional requirements. Below are typical scenarios that illustrate how we guide customers in choosing the right combination.

| Scenario | Recommended Process | Recommended Fibre Type | Why This Combination Works |

|---|---|---|---|

| Large household appliance (e.g. water filter unit) | Dry-press | Recycled or A4 virgin pulp | Thick walls (2–3 mm) provide shock absorption; lower mold cost for bulk parts. |

| Premium skincare set | Wet-press | Bamboo or Bagasse pulp | Smooth finish adds perceived value; fine details and lightweight design. |

| Take-away food bowl / clamshell | Wet-press | Bagasse pulp | Food-safe, natural white tone, stackable, compostable. |

| Electronics inner tray (smartphone or accessory) | Wet-press | A4 virgin or Bagasse pulp | Thin, precise, dimensionally stable for automated assembly lines. |

| Industrial component protector | Dry-press | Recycled pulp | Maximum strength and cost efficiency for non-display packaging. |

Because food-service packaging always prioritizes hygiene, smoothness, and stackability, it is almost exclusively made by wet-press technology. Dry-press is reserved for industrial or structural packaging where wall thickness is an advantage.

Cost Drivers and Questions to Ask Your Supplier

Many buyers assume material choice is the main factor in cost, but in reality, process parameters and mold design are equally important. Here’s what influences total cost most:

Many buyers assume material choice is the main factor in cost, but in reality, process parameters and mold design are equally important. Here’s what influences total cost most:

- Mold complexity and number of cavities

- Wet-press molds are multi-cavity to balance slower cycles; higher upfront cost.

- Dry-press molds can be simpler and single-cavity.

- Cycle time and energy use

- Hot-pressing in dry-press takes seconds; in wet-press it takes minutes.

- Trimming requirements

- Some dry-press products skip trimming entirely.

- Raw-material cost per ton

- Recycled < A4 < Bagasse < Bamboo.

- Finishing and dyeing

- Optional; affects both cost and lead time.

When communicating with suppliers, asking the right questions saves both sides time:

- What production process do you recommend—dry or wet press?

- How many cavities will each mold include?

- What is the expected wall thickness and surface finish?

- Which fiber is the dominant raw material, and what other fibers are blended in?

- Is the product suitable for direct food contact?

- What is the estimated unit cost at my expected volume?

- What is the lead time for mold fabrication and first samples?

At InNature Pack, we typically provide a side-by-side simulation showing how each process and fiber combination affects both mold cost and product price. This helps buyers visualize trade-offs before committing.

Why Brands Choose InNature Pack

Selecting the right combination of process and fiber can look complicated—but it’s our everyday job. InNature Pack integrates both dry-press and wet-press production lines, supported by engineering teams experienced in mold design, forming simulation, and cost optimization.

We source and blend only renewable fibers such as bagasse, bamboo, and A4 white pulp, ensuring consistent performance, color tone, and safety for food contact. For industrial projects, we also supply recycled-pulp options where sustainability and strength outweigh cosmetic requirements.

Beyond manufacturing, we assist clients through each step:

- Concept review & engineering consulting: we analyze product geometry, weight, and packing density to recommend the right process.

- Mold design support: we design forming, hot-press, and trimming molds as a coordinated set to ensure efficient production.

- Material selection guidance: we test blends of different fiber ratios to achieve your target strength and aesthetic.

- Sample prototyping & testing: we provide small-batch prototypes for fit, drop, and stacking tests before full-scale production.

All these steps aim to let our clients focus on their products—not on mastering pulp science.

Conclusion: Making It Simple for You

At first glance, molded-pulp packaging seems filled with technical variables—fiber sources, long- and short-fiber ratios, process routes, mold types, cavity counts, drying cycles. For a packaging engineer, that’s the fun part. For most buyers, it’s simply too much detail.

Here’s the truth: custom pulp packaging doesn’t have to be complicated.

When you work with InNature Pack, you only need to tell us:

- What you want to pack

- The look or feel you’re aiming for

- Your expected order volume and budget range

Our engineers will handle everything else—evaluating fiber blends, deciding between dry- or wet-press, designing efficient molds, and balancing performance with cost.

You can stay focused on your product and your customers while we make sure every molded-pulp piece performs exactly as it should—beautifully, sustainably, and reliably.

Ready to explore the best material and process for your next packaging project?

Contact the InNature Pack team for a tailored recommendation and sample plan—

we’ll take care of the complexity so you don’t have to.